With the development of the lifting industry, the European wheel is a step by step alternative to the traditional wheel, the European wheel's compact structure, small size, load-bearing, low noise, etc., to meet the needs of high-standard production workshop, the market demand for European products will continue to expand with the development of society, in order to meet the needs of the majority of customer demand, the European/traditional lifting accessories selection, supporting, our company has a professional and technical team for you! Tailor-made.

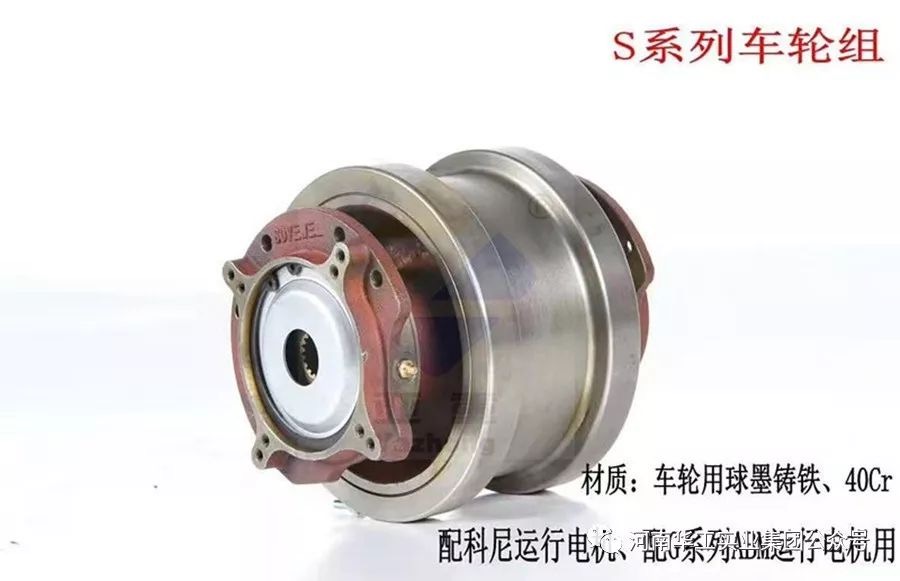

The company's European wheel is divided into ductile iron wheel (S-S series and S-G series) and F series wheel

Ductile cast iron wheels

Compact structure, few parts, easy to assemble.

Adopting high-strength ductile iron wheel QT700-2, with good abrasion resistance and vibration damping.

Adopt templated design and supply in sets.

DING standard internal spline 5480 connection, automatic positioning, easy disassembly.

Provide direct 110, 140, 200, 250, 315(320), 400, 500 wheelsets.

Another non-standard wheelsets can be provided according to customer requirements (customized forged steel wheelsets 65Mn and 42CrMo wheelsets are available).

Bearing housing material QT500 ductile cast iron.

S-S series with Konecranes running motors, conventional wheel material is ductile cast iron (QT700-2).

S-G series with ABM's G series reducer, conventional wheel material 40Cr

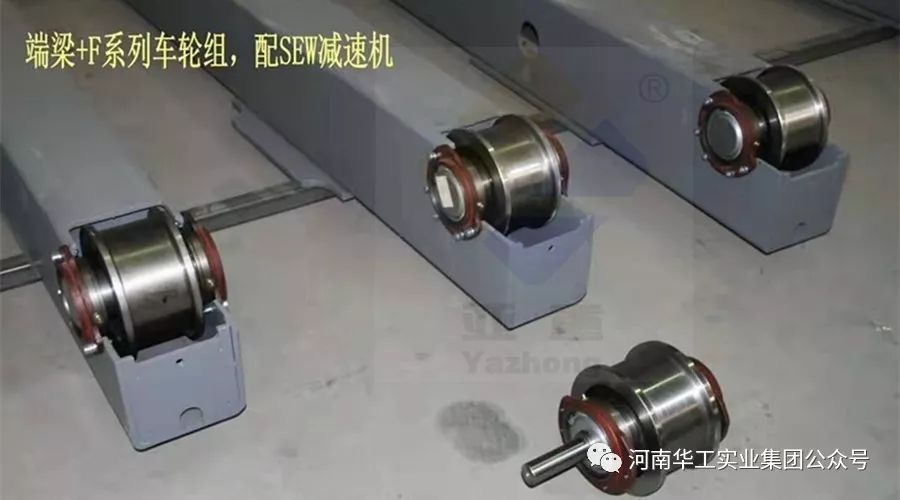

F series wheel

With F, K series reducer, conventional wheel material is 40Cr, 42CrMo, shaft material is 40Cr, with HRB original bearings, the whole wheel is tempered, and the bearing housing material is spherical ground cast iron.

Wheel set inspection precautions

1、The axle hole of the wheel set needs to be inspected regularly, and the defects and depth of the axle hole are strictly regulated. If it exceeds the specified amount, it is necessary to replace the new parts.

2. If the radial wear of the pulley groove of the wheel set exceeds 32% of the wall thickness, replace it with a new one. No more than the maintenance, maintenance of the pitch can not be more than 0.5 millimeters.

3, the wheel set of pulleys in maintenance, need to check whether there is no crack, parts of the journal wear is not more than 40%, or replace the new parts.

4, crane parts of the wheel set needs to be disassembled when overhauling, after inspection and repair, it should be assembled in time. After assembly is required to test

Contact: Mrs.Peng

Phone: 86-15910902294

E-mail: pengying@hjwm.com.cn

Whatsapp:+86 13713229714

Add: 140 meters north of Dongyangze Road, Guiling Avenue, Changyuan City, Xinxiang City, Henan Province,China

We chat