Material Selection: High-quality steel is chosen for its strength and durability, often with specific alloys to enhance wear resistance.

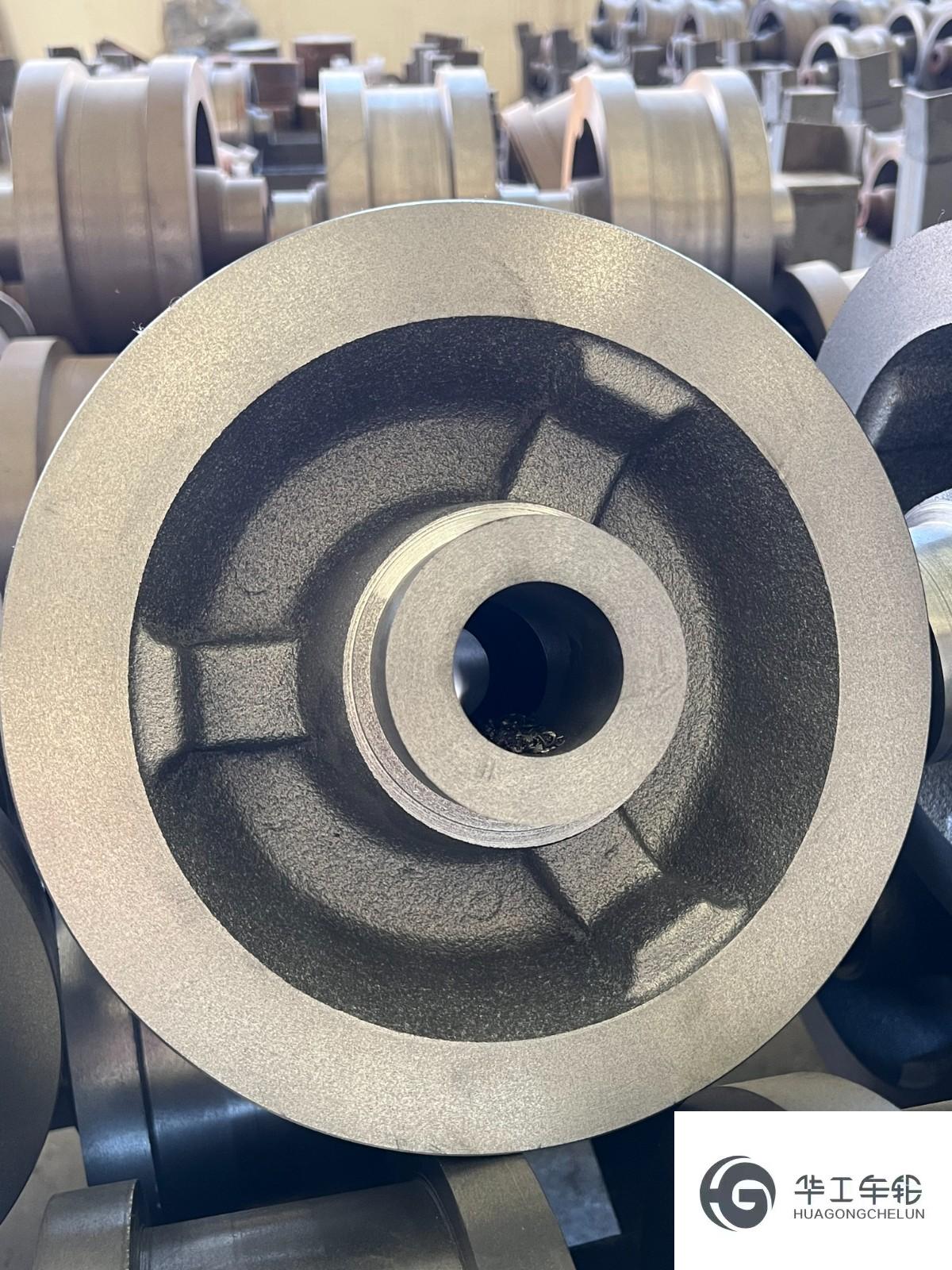

Forging or Casting: Depending on the size and design, the wheel can be forged or cast. Forging involves shaping the heated metal using compressive force, while casting involves pouring molten metal into a mold.

Heat Treatment: After shaping, the wheels undergo heat treatment to optimize their mechanical properties such as hardness and toughness. This step ensures the wheels can withstand heavy loads and frequent use.

Machining: Precision machining is crucial to achieve the required dimensions, surface finish, and balance. This step includes turning, milling, and grinding to refine the shape and ensure uniformity.

Surface Treatment: To enhance durability and corrosion resistance, the wheels may undergo surface treatments such as shot blasting, painting, or galvanizing.

Quality Control: Throughout the process, rigorous quality checks are performed to verify dimensions, material properties, and overall compliance with specifications.

Assembly: Once finished, the wheels are assembled onto axles or shafts, ensuring proper fit and alignment.

Testing: Finally, the assembled wheels undergo performance tests to ensure they meet operational requirements and safety standards.

Each step in this process is crucial to ensure that crane wheels can safely and efficiently handle the demanding tasks they are designed for.

Contact: Mrs.Peng

Phone: 86-15910902294

E-mail: pengying@hjwm.com.cn

Whatsapp:+86 13713229714

Add: 140 meters north of Dongyangze Road, Guiling Avenue, Changyuan City, Xinxiang City, Henan Province,China

We chat