80T Electromagnetic Overhead Crane for Scrap Steel Handling

Time:2022-03-25 11:02:51

Introduction:

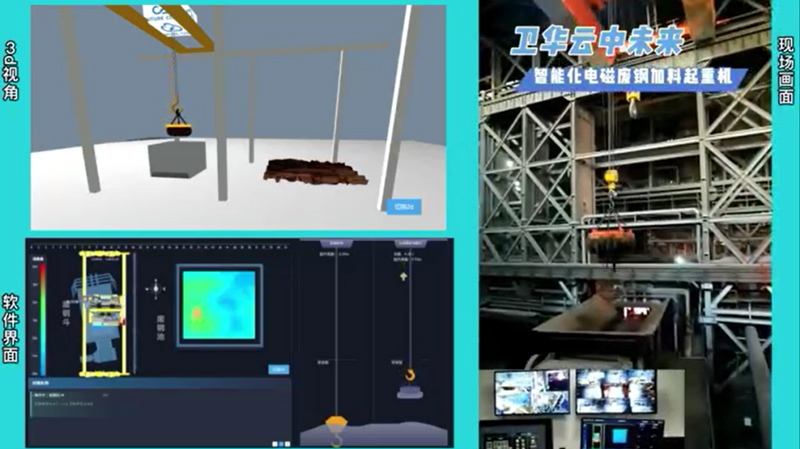

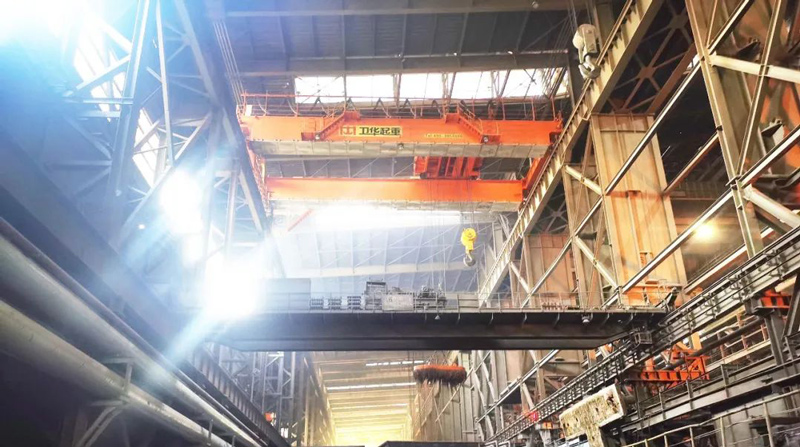

Weihua made a capacity 80/32T metallurgy overhead bridge crane for an unmanned steel plant. This crane is designed with a span of 24.6m and a rail surface elevation of 29.26m, and the lifting spreader is a hook with round electromagnetic disc lifter.

Features:

1. This crane owns the world leading anti-sway automatic positioning technology with smooth running, accurate position and reliable performance;

2. It has the functions of 360-degree real-time monitoring, intelligent anti-collision, to ensure On-site safety of personnel and equipment;

3. The software adopts the AICraneWMSv3.0 warehouse management system, and is matched with the original digital twin 3D screen of the lifting industry to realize all-round data management and intelligent scheduling;

4. The intelligent 3D scanning system updates the on-site material data in real time, to ensure accurate and efficient lifting operations.

5. The crane adopts the configuration of double hoisting mechanism. The main hoist is used for ladle handling, and the deputy hoist is intelligently operated to feed the scrap steel preheating production line. The operation of the main and deputy lifts is realized by the AICrane intelligent system to achieve safety interlocking, independent control, and non-interference.

6. The system is used in metallurgical workshops, and multiple cranes work together at high and low levels. The system ensures the safe and efficient operation of cranes through the original multi-level security protection system.

7. Through the effective electromagnet control strategy, the system can prevent accidental material leakage and magnetic discharge during the operation of the crane, and ensure the safety of field equipment and personnel.

8. The AICrane system arranges multiple cameras in the crane and important working positions of the workshop, 360 degrees without dead angle to view the scene, and the video delay is less than 200ms, which effectively supports the customer's remote manual operation.

9. The AICrane Digital Twins visualization platform independently developed by Weihua realizes the two-dimensional and three-dimensional display of on-site data and can be switched freely. The workshop area is drawn in equal scale, and it acts synchronously with the on-site equipment to truly restore the on-site operation situation. The system can be perfectly integrated with the AICrane unmanned crane system, sharing workshop and equipment data, and displaying process information such as logistics, warehousing, and tasks through flexible configuration. It can be widely used in process optimization, digital large screen, equipment monitoring, Workshop management and other application scenarios can fully meet the all-round needs of customers.

10. The system has on-site remote control, remote manual, semi-automatic, and fully automatic operation modes, which can complete normal automatic operation and handle various needs such as special operations.

At present, the AICrane system has been applied and implemented in many large steel mills such as cold-rolled coils, bar storage, blast furnace slag grabbing, scrap loading, ladle transfer and other scenarios. The system is deeply integrated with production scenarios, and runs smoothly and reliably. It is a good help for heavy-duty logistics, assisting the transformation and upgrading of smart steel in traditional steel plants, meeting customers' needs for digitalization, networking, and intelligence, and winning much praise from customers.

Contact: Mrs.Peng

Phone: 86-15910902294

E-mail: pengying@hjwm.com.cn

Whatsapp:+86 13713229714

Add: 140 meters north of Dongyangze Road, Guiling Avenue, Changyuan City, Xinxiang City, Henan Province,China

We chat