Advantages of euro-style multi-function gantry crane 60ton:

1. The overall height of the FEM/DIN double girder gantry crane crane can be 20%~25% lower than that of traditional crane with weight reduced by 20%~30%.

2. The maximum wheel pressure can deduct by 15% ~ 20%.

3. The small size of this crane can increase the working area.

4. With the lightness structure it can cut the construction costs.

5. Each spare parts on the crane are design to series standard modulus, which makes easy for the product combination.

Product Description

The euro-style multi-function gantry crane 60ton adopt modularization design for lifting mechanism with light weight, alloy-steel forging wheels and intelligent control.

Features of euro-style multi-function gantry crane 60ton:

1. Adopt modularization design for lifting mechanism, FEM/DIN standard, light weight

2. High-strength alloy-steel forging wheels

3. No welded legs for profile steel

4. Capsule cab with broad vision

5. Rectangular steel- pipe handrail

6. Hard tooth surface reducer imported from Germany

7. Power supplied by engineering drag chain

8. World's leading anti-sway control technology

10. Advanced fabricated technology

11. Low-energy and maintenance-free

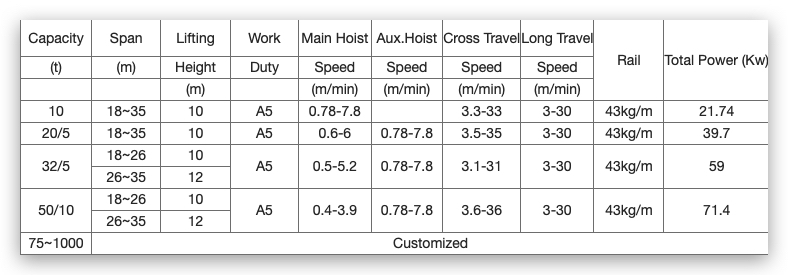

Specification :

Advantages of euro-style multi-function gantry crane 60ton:

1. The overall height of the FEM/DIN double girder gantry crane crane can be 20%~25% lower than that of traditional crane with weight reduced by 20%~30%.

2. The maximum wheel pressure can deduct by 15% ~ 20%.

3. The small size of this crane can increase the working area.

4. With the lightness structure it can cut the construction costs.

5. Each spare parts on the crane are design to series standard modulus, which makes easy for the product combination.

6. The independent modulus is convenient for the transportation.

7. Standard modulus production can ensure stability quality of the product and shorten the delivery period.

8. Sandblasting pretreatment for the steel plate with surface quality reaching Sa2.5.

9. Using digital cutting machine to cut the web plate to ensure the smooth and precision of the camber curvilinear.

10. Main welding seam adopts auto arc merged welding, Ultrasonic, X-ray nondestructive inspection.

11. The crane and trolley frame adopts floor type boring machine to ensure the flatness of the machine side.

12. The safety supervises system is equipped with overload limiter, and on the monitor it can display the loads value and remind the operator to prevent the overload happening.

13. Before the start, the entire controller will start self-checking including: power voltage, default phase, the effective of each safety protective device and zero position of the button.

14. Adopts imported with original packaging from Germany, The brake force shall no less than 2160N/mm2, and its safety factor shall no less than 5.

>>> FAQ

If you are interested in our products, please no hesitate to contact us with following parameters:

1. Crane Capacity

2. Crane Span

3. Lifting Height

4. Work Duty(A3/A4 /M3...)

5. Traveling Length

Control Metho

Contact: Mrs.Peng

Phone: 86-15910902294

E-mail: pengying@hjwm.com.cn

Whatsapp:+86 13713229714

Add: 140 meters north of Dongyangze Road, Guiling Avenue, Changyuan City, Xinxiang City, Henan Province,China

We chat