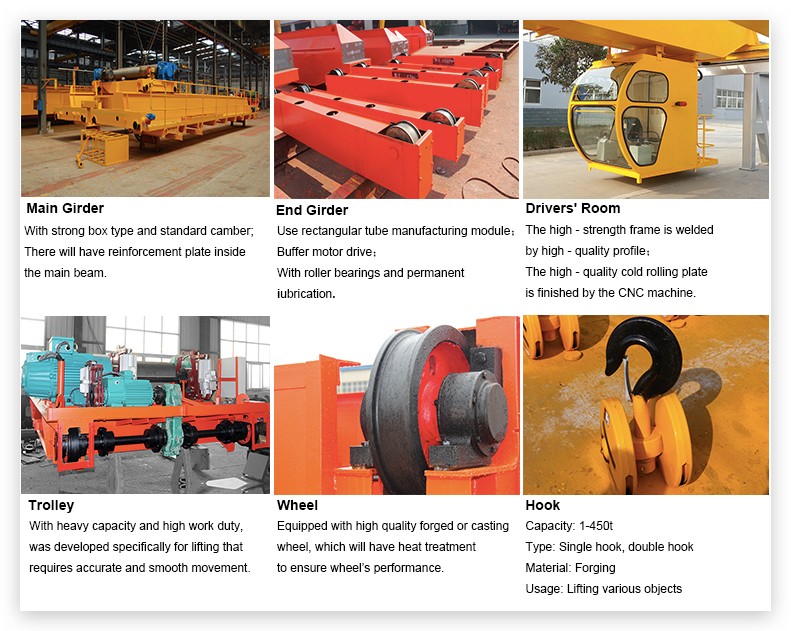

QY insulation double girder overhead crane is composed with girder frame, crane travel device, and electric trolley with lifting and traveling device. There are pave the rail for the trolley traveling on the main girders.

Assemble the moving table on the outside of the two main girder, one side is prepare for the assemble and maintenance the crane move device, another side is prepare for the assemble of the trolley conductor device.

There is a full-view cabin under the main beam, and a combined console or a single control box is installed in the cabin. A side long ladder is assembled between the cabin and the mobile platform, and the main beam and the end frames on both sides are connected to the joint points in the middle.

Overview

Essential details

Applicable Industries:

Construction engineering machine, Genera Manufacturing Industry, Automotive, Foundry industry,Pulping and Paper Making

Video outgoing-inspection:Provided

Machinery Test Report:Provided

Warranty of core components:1 Year

Core Components:Engine, Motor, Gear

Condition:New

Rated Lifting Moment:No limit

Max. Lifting Load:800ton

Max. Lifting Height:20M, Other

Span:32M or customized

Place of Origin:Henan, China

Warranty:1 Year

Weight (KG):12500 kg

Color:Yellow or optional

Painting:3 layer anti-rust painting

Main electrical parts:Siemens or Simens brand

Material:Q235, Q345 carbon steel

Weight overload protection device::Included

Voltage loss protection function::Included

Emergency stop:Included

Polyurethane materials buffer:Included

Turn key project:Can provide

Supply Ability

Supply Ability

10000 Set/Sets per Year

Packaging & delivery

Packaging Details

1. Electric parts are packed by high quality plywood crate, to reduce distortion in conveying

2. Main beams, end beams and electric hoist are packed by plastic woven cloth. It can reduce abrasion when transport

3. If the size is too big, usually by bulk ship or by container after truncation

Port

any ports of China, depends on client inquiry

QY insulation double girder overhead crane is composed with girder frame, crane travel device, and electric trolley with lifting and traveling device. There are pave the rail for the trolley traveling on the main girders.

Assemble the moving table on the outside of the two main girder, one side is prepare for the assemble and maintenance the crane move device, another side is prepare for the assemble of the trolley conductor device.

There is a full-view cabin under the main beam, and a combined console or a single control box is installed in the cabin. A side long ladder is assembled between the cabin and the mobile platform, and the main beam and the end frames on both sides are connected to the joint points in the middle.

Main Features

1. Overhead traveling on the steel structure, normally used in workshop, heavy working duty A6.

2. Strong box type steel structure of crane.

3. Soft start, 3-5 speeds to operate, very stable to lift and running.

4. Six direction action, to make sure the enough wide working area.

5. Insulation function

6. Full safety system as follows:

Weight overload protection

Emergency stop system

Over current protection,Short-circuit protection

Phase sequence protection

Zero position protection

Voltage loss protection

Limit switch and stopper for crane long traveling and cross traveling

Lifting overhigh and overlow limit switch

Detailed Images

>>> FAQ

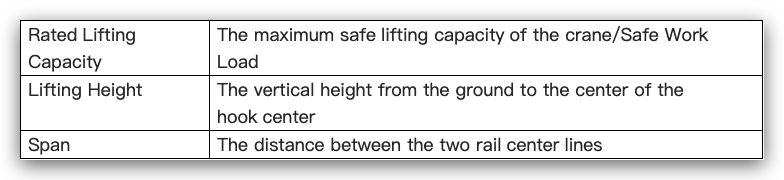

If you are interested in our products, please no hesitate to contact us with following parameters:

1. Crane Capacity

2. Crane Span

3. Lifting Height

4. Work Duty(A3/A4 /M3...)

5. Traveling Length

Control Method:

Standard operating methods:

A: remote control with push buttons

B: cabin(space capsule seat) control with joystick.

Choose any type as you like.

7. Any spare parts like rails, bus-bar?

8. Local Power Supply

9. Quantity

10.Lifting Object

11. Desitination Port

More details or drawings, the better.

Notes: The parameters can be customized according to your specific needs.

After your selection

1. We will count cheapest shipping cost and make invoice to you at once.

2. Test each machine before delivery to ensure their quality, then send out to you after your

payment.

After-sale Service

1. Installation service of overhead crane available with:

Video tutorial support for whole installation process.

7/24 remote assistance for crane installation guidance and commissioning.

2. We are very glad that customer give us some suggestion for price and products.

3. If you have any question, please contact us freely by E-mail or Telephone

Contact: Mrs.Peng

Phone: 86-15910902294

E-mail: pengying@hjwm.com.cn

Whatsapp:+86 13713229714

Add: 140 meters north of Dongyangze Road, Guiling Avenue, Changyuan City, Xinxiang City, Henan Province,China

We chat