I. Main components of the wheel set and its process

Common standard wheel sets mainly have wheels, wheel axles, bearing boxes, bearings, through boring cover and some seals.

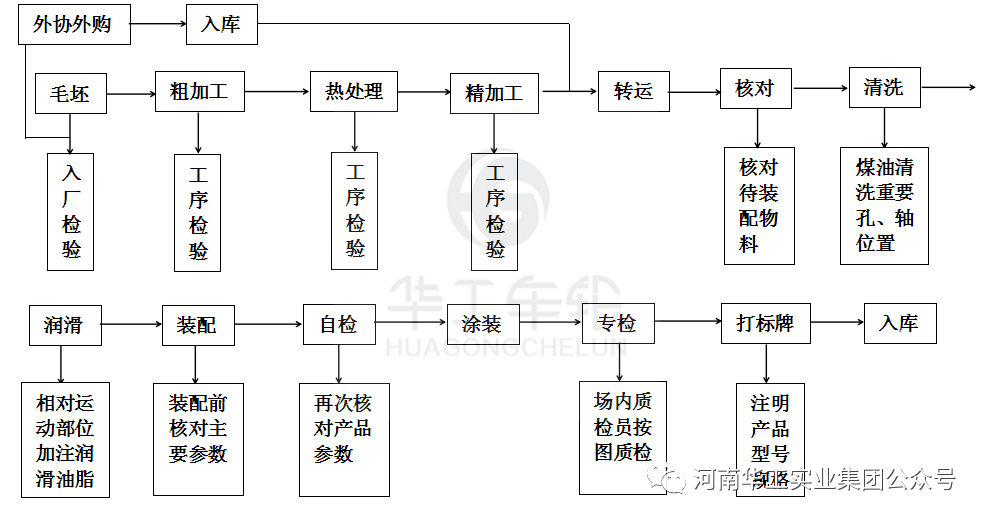

The main process flow of wheel set processing:

II. Quality assurance measures for the production process of wheel sets

To provide customers with personalised and customised services, priority is given to the selection of materials according to customer requirements, and the selection is made on the basis of merit in the catalogue of qualified suppliers to meet the diversified requirements of customers. In the absence of customer requirements, materials are generally selected with reference to national and industry standards, as follows:

(1) Wheels

ZG50SiMn is selected by default, and a series of technological measures such as quenching process are adopted to make the wheel tread hardness at HB330-380, and the hardness of the hardness layer at a depth greater than or equal to 20mm is not less than 260HB, which improves the wear resistance and impact resistance of the wheel, thus increasing the service life of the wheel.

(2) Wheel axle

Technical personnel design drawings according to customer requirements → according to the drawings of material → rough machining → heat treatment (tempering) after passing inspection → finishing after passing inspection → inspection after passing into storage.

The common materials used for wheel axles are 45 and 40Cr, which are characterised by high strength, good plasticity and toughness, good machinability and good overall mechanical properties after tempering.

(3) Bearing box

Our wheel bearing box is made of ductile iron (QT400-15), which has good plasticity and toughness, good weldability and machinability, and high impact toughness at room temperature.

(4) Bearings

The bearings of our company's wheel sets are regular products of Ha Shaft, Wa Shaft and Luo Shaft manufacturers, and all the rolling bearings of the wheel sets are used, which have low running resistance, high load bearing, easy assembly and maintenance. Our company gives preference to self-aligning spherical roller bearings, which can compensate for installation errors and frame deformation to a certain extent.

Three, team guarantee

Our company has many years of experience, skilled and responsible production and quality inspection team, supplemented by excellent production equipment represented by CNC machining centres, and advanced professional inspection tools and gauges, so as to ensure that the entire production process is orderly, high quality and efficient, so as to truly achieve, not to accept bad, not to produce bad, not to flow bad, to survive on quality, to provide customers with high quality and low price We will provide our customers with quality products at low prices and improve their competitiveness and satisfaction so as to achieve a win-win situation.

Contact: Mrs.Peng

Phone: 86-15910902294

E-mail: pengying@hjwm.com.cn

Whatsapp:+86 13713229714

Add: 140 meters north of Dongyangze Road, Guiling Avenue, Changyuan City, Xinxiang City, Henan Province,China

We chat