1. Application scope: Crane accessories.

2. Drum units is constituted by drum, shaft, gearwheel, hub, bearing body and bearing.

3. The material of drum is usually no less than HT20-40 cast iron, ZG25,ZG35 or Q235B, Q345B welding steel plate is also able to be the material for special needs.

4. Drum units applies to the large tonnage crane machinery which needs high-performance.

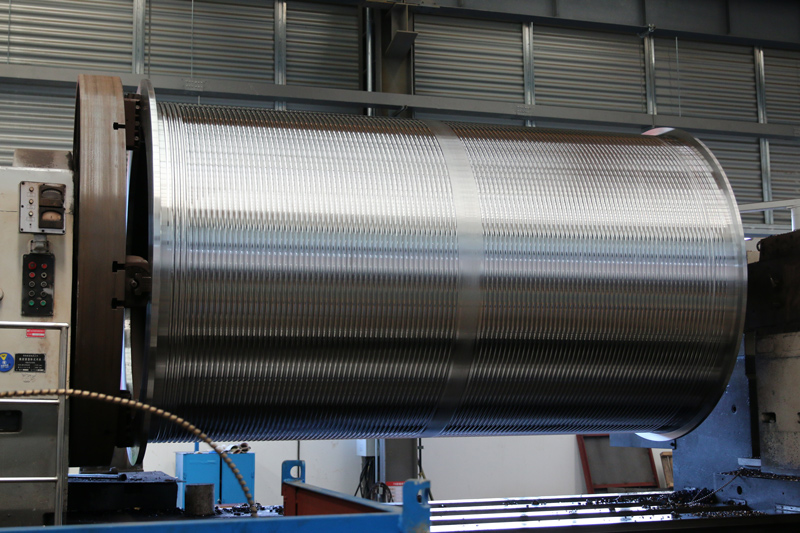

1. Wire Rope Reel/Drum Application: Crane accessories for reeling wire rope as a winch or electric hoist.

2. Drum units is constituted by drum, shaft, gearwheel, hub, bearing body and bearing.

3. The material of wire rope drum is usually no less than HT20-40 cast iron, ZG25,ZG35 or Q235B, Q345B welding steel plate is also able to be the material for special needs.

4. Wire rope drum units applies to the large tonnage crane machinery which needs high-performance.

For Safety

1. The surface of the single-layer winding drum is cut with a spiral groove with an arc-shaped section to increase the contact area between the wire rope and the drum body, and to fix the winding position of the wire rope on the drum to avoid the influence of adjacent wire ropes rubbing against each other.

2. The surface of the drum body of the multi-layer winding drum is usually a smooth surface without spiral grooves, and there are flanges at both ends of the drum body to prevent the wire rope from slipping out. The disadvantage is that the wire ropes are closely arranged, and the layers are stacked and rubbed against each other, which has a great impact on the life of the wire rope. Among the structural dimensions of the reel, the key dimension that affects the life of the wire rope is the calculated diameter of the reel.

3. In order to ensure the reliable fixation of the wire rope tail and reduce the stress on the pressure plate or wedge, when the pick-up device is lowered to the lower limit position, in addition to the fixed loop of the wire rope, 1.5 to 3 safety loops should be reserved on the reel. Known as the load-relief ring, this has been taken into account in the design of the reel. In use, the more loops of the wire rope tail are retained, the smaller the force on the pressure plate or wedge of the rope tail, and the safer it is. If the lower limit position of the pick-up device is too low and the remaining number of wire ropes on the drum is less than the designed number of safe loops, the force on the tail of the wire rope will exceed the pressing force of the pressure plate or wedge, resulting in the wire rope was pulled off and the heavy object fell.

Wire Rope Drum Packing

>>> FAQ

If you are interested in our products, please no hesitate to contact us with following parameters:

1. Crane Capacity

2. Crane Span

3. Lifting Height

4. Work Duty(A3/A4 /M3...)

5. Traveling Length

Control Method:

Standard operating methods:

A: remote control with push buttons

B: cabin(space capsule seat) control with joystick.

Choose any type as you like.

7. Any spare parts like rails, bus-bar?

8. Local Power Supply

9. Quantity

10.Lifting Object

11. Desitination Port

More details or drawings, the better.

Notes: The parameters can be customized according to your specific needs.

After your selection

1. We will count cheapest shipping cost and make invoice to you at once.

2. Test each machine before delivery to ensure their quality, then send out to you after your

payment.

After-sale Service

1. Installation service of overhead crane available with:

Video tutorial support for whole installation process.

7/24 remote assistance for crane installation guidance and commissioning.

2. We are very glad that customer give us some suggestion for price and products.

3. If you have any question, please contact us freely by E-mail or Telephone

Contact: Mrs.Peng

Phone: 86-15910902294

E-mail: pengying@hjwm.com.cn

Whatsapp:+86 13713229714

Add: 140 meters north of Dongyangze Road, Guiling Avenue, Changyuan City, Xinxiang City, Henan Province,China

We chat